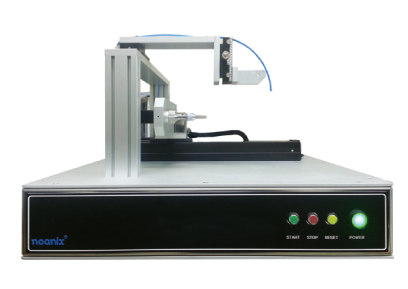

Coaters(NoaCoater®)

Spray Coaters

Dip Coaters

Inner Coaters

Spray Coaters

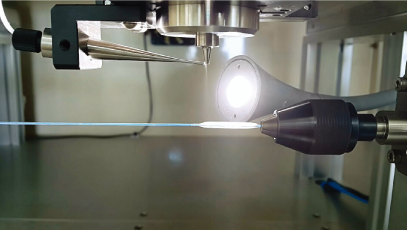

- NoaCoater for DES(Drug- eluting Stent)

- NoaCoater for Balloon

- NoaCoater for Artificial Blood Vessel

- NoaCoater for Blood Collection Tubing/Syringe

- Coating machines for various medical applications

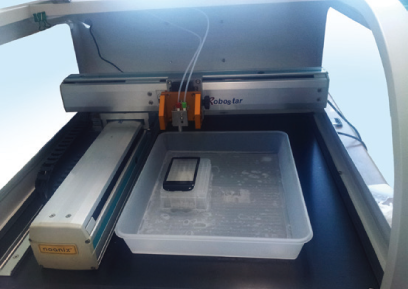

Dip Coaters

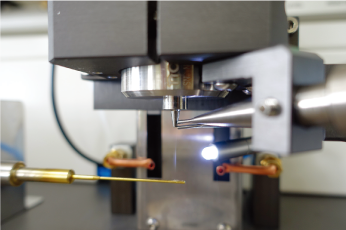

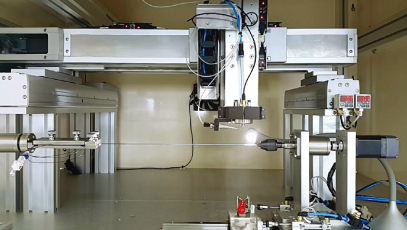

Inner Coaters

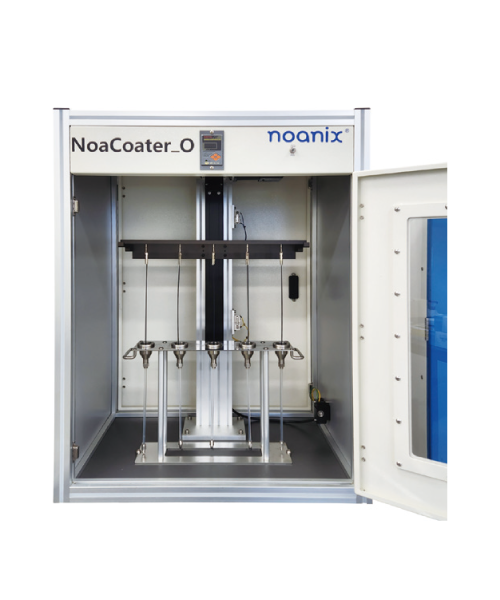

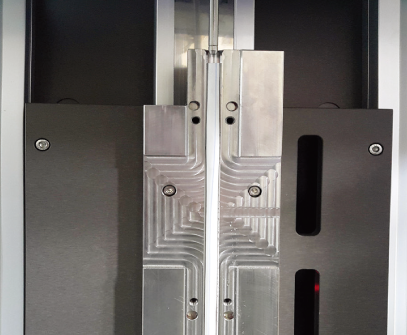

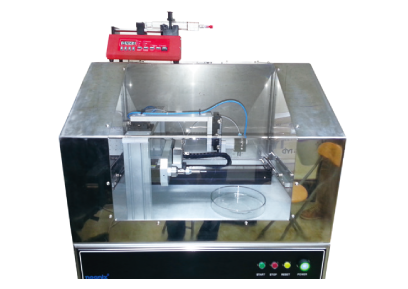

Internal Coating System for hydrophilic coating

- For inside coating for hydrophilic coating

Includes

– Size of 950 x 750 x 1150(Customised)

– Produces 9 Tubes at one time(Customised)

Housing Specifications

– Construction 316 stainless steel, aluminum

System Specifications

– Control : PID Control

– Reservoir Volume : 1.5 L (Customised)

– Device & Coating Length : max. 550mm (Customised)

– Coating Inner Diameter : 3~35mm(Customised)

Requirements

– Power : 110-220VAC, 50/60hz 20A(Customised)

– Air Operating : Minimum 20 psi

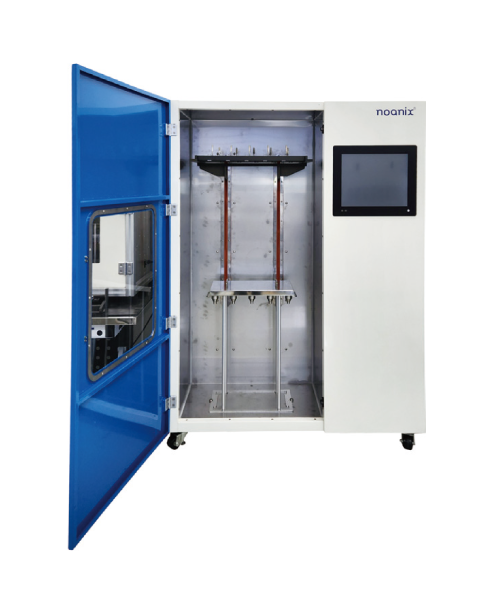

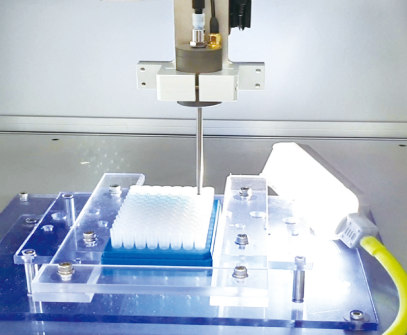

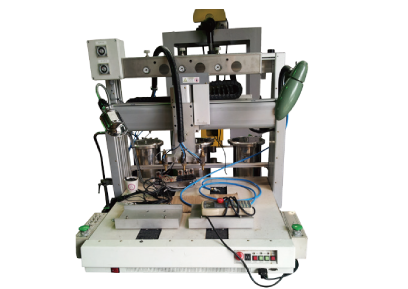

- Inner coater for internal coating

Includes

– Size : 950 x 750 x 1150(Customised)

– Produces 100 cartridges at one time (Customised)

Specifications

– Control : Pc Control

– Reservoir Volume : max. 1L (Customized)

– Coating length : Customized

– Coating Diameter : Customized

Requirements

– Power : 110-220VAC, 50/60Hz 20A (Customized)

– Air Operating : Minimum 20 psi