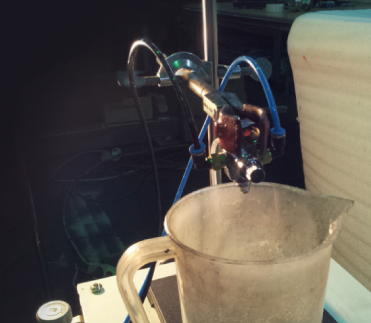

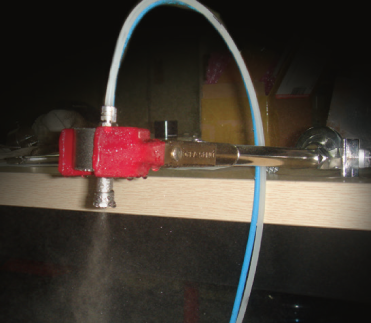

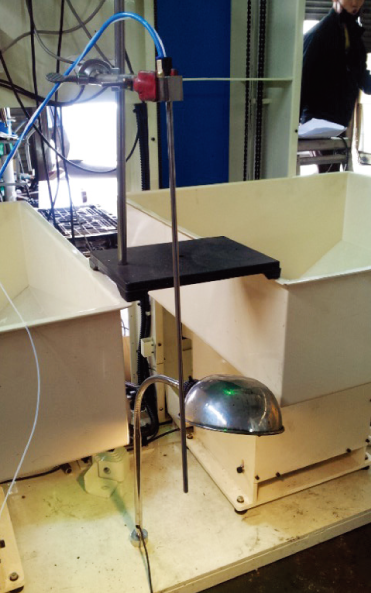

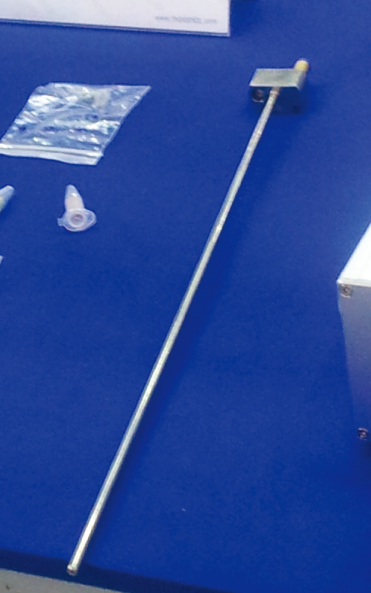

Air-assisted Nozzle(Veljet nozzle)

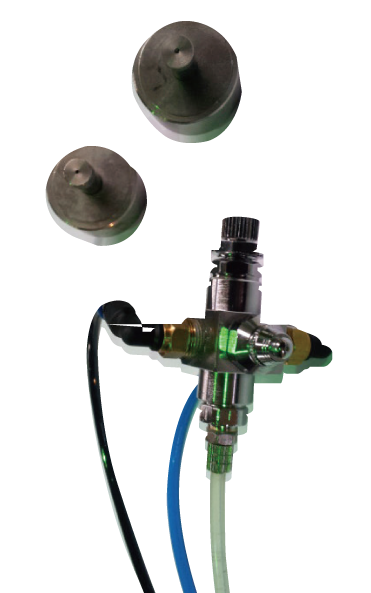

The Veljet Atomizing Nozzle is designed for applicationsrequiring highly consistent and precise micro-coating. The nozzle is manufactured from 316 stainless steel and contains no internal moving parts or valves, ensuring stable long-term performance and minimal maintenance.

Unlike conventional air atomizing nozzles that rely solely on pressure and timing, the Veljet system delivers a precisely metered fluid stream into a controlled gas flow, forming a uniform atomized spray field through a precision orifice. This results in: Stable conical or beam spray patterns Excellent coating repeatability. Reduced material waste Compatibility with viscous fluids and suspensions. The Veljet nozzle is particularly effective for medical and pharmaceutical manufacturing, especially where validated and solvent-free processes are required.

- Technical Highlights

- •Fluid compatibility: aqueous, viscous solutions, suspensions

- •Viscosity capability: up to 100,000 cps

- •Spray dose: below 1 mg per spray

- •Custom nozzle diameter & length available

- •Designed for integration with precision dispensing systems

- Features & Benefits

- • Ultra-low volume spray down to 0.3 μL

- • High repeatability and coating uniformity

- • Droplet size range of 5–50 µm

- • Low-pressure spray operation

- • Atomization achieved from 3 psi

- • Autoclavable design

- • Corrosion resistant structure

- • 316 Stainless Steel

- • The outer diameter of the nozzle is between 2.5mm and 5mm.

- • Nozzle length options up to 100 mm

- • Suitable for heated processes

- • No moving parts (high durability & reliability)

- • Compatible with alternative gases

- • Suitable for high-speed manufacturing processes

- General Applications

- • Silicone atomization

- • Syringe barrel coating

- • Needle inner/outer surface coating

- • Catheter coating

- • Blood collection tube processing

- • Pharmaceutical container coating

- • Medical tube coating

- • Atomizing emulsions & reagents

- • Spray drying processes

- • Electrolyte atomization

- • Solvent-free lubrication processes

- • Fine coating for precision medical devices

- • Many other applications