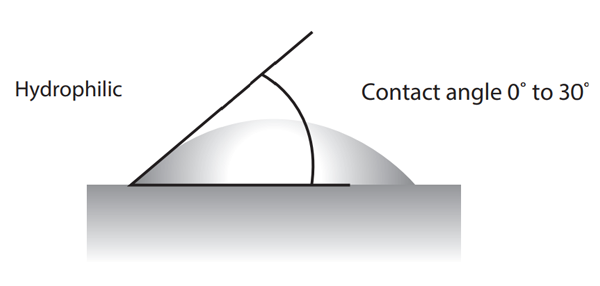

Hydrophilic Coatings

Heat curable coatings

UV curable coatings

Heat curable coatings

- Introduction

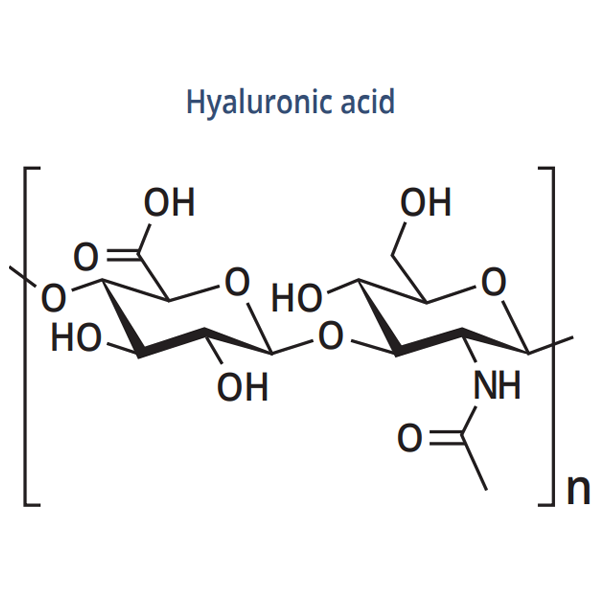

- Noanix’s main hydrophilic coating solution uses hyaluronic acid, which is an FDA-approved natural polymer with excellent biocompatibility and low rejection reaction, so it is used in various fields of our body, such as ophthalmic supplements, intra-articular injections, artificial tears, and wound healing.

- HA is a kind of mucopolysaccharide, has a water content of 6000 times, is a method of attracting moisture in the air, and is stable as EWG 0 grade. In addition, it has high lubricity and durability, and was developed to be applied to various medical devices

- Advantages

- Super Lubricious

- Really biocompatible

- Extremely durable

- Substrates to be coated

- Pebax

- PEEK

- PP

- PE

- PC

- TPU

- PMMA

- Teflon

- Silicone

- Metals – Ni, SUS

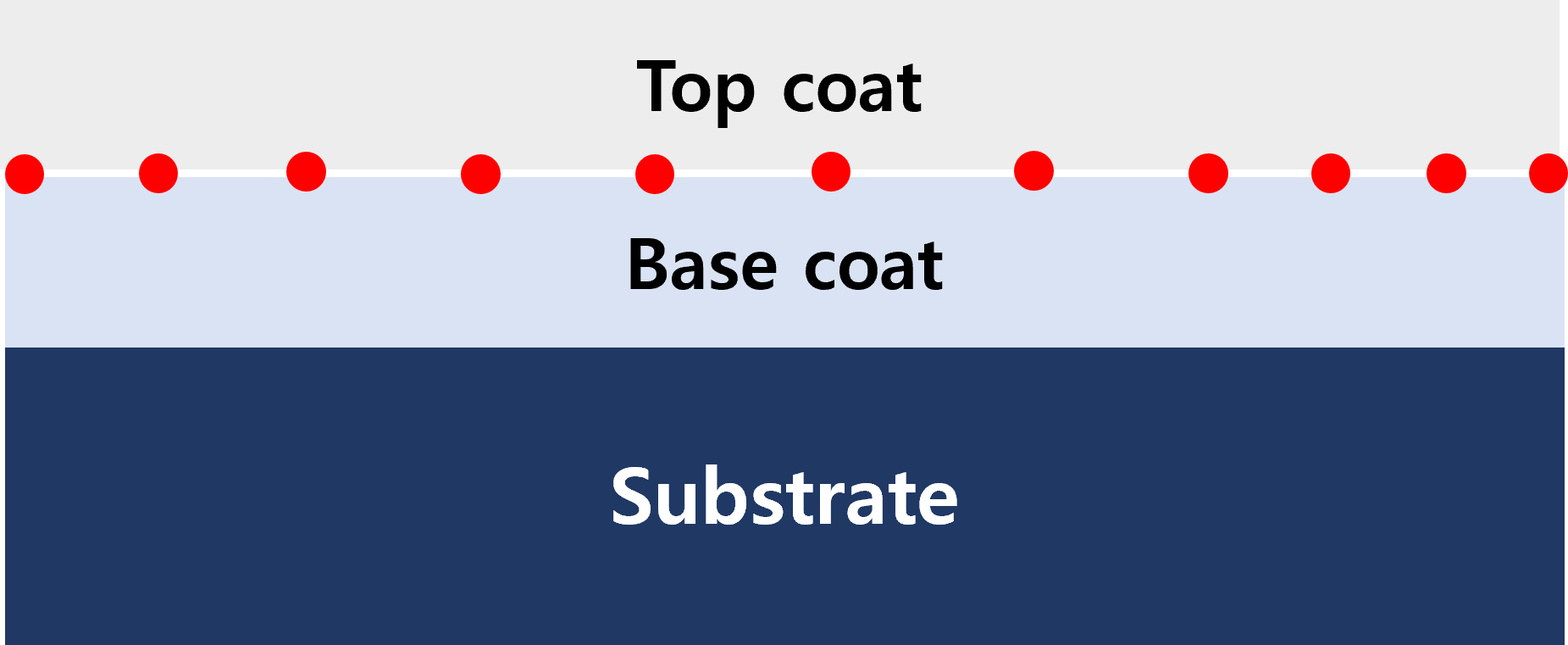

- Primer

- Covalently bonded with HA Top Coating

- Generally no pretreatment required

- Custom tuning possible

- Several base coats versions available

- Noanix Bilaminar Coating’s Advantages

- Biocompatible(Natural polymer, HA)

- Extremely durable and lubricious

- Various coating solutions(HA main, PVP and PU optional)

- FDA approved ingredients

- Very low particles

- Various basecoats and topcoats versions

- Safe, eco-friendly and non-flammable solvents used

- Batch process for mass production

- Viscosity controllable

- Bilaminar system

| OB system | DP system | I system | New system | |

|---|---|---|---|---|

| TPU | ◎ | |||

| PEBAX(hard) | ◎ | ◎ | ||

| PEBAX(moderate) | ◎ | *○ | ||

| PEBAX(soft) | ◎ | *○ | ||

| PP | ○ | ◎ | ||

| PC | ◎ | |||

| Silicone | ※◎ | |||

| PE | ◎ | *◎ | ||

| PTFE | ◎ | *○ | ||

| ETFE | ◎ | *◎ | ||

| SS | ※◎ | |||

| Nitinol | ※◎ | |||

| PMMA | ◎ | |||

| PVC | ○ | ◎ | ||

| PEEK | ◎ |

*: Pretreatment required

※: Triple coating recommended

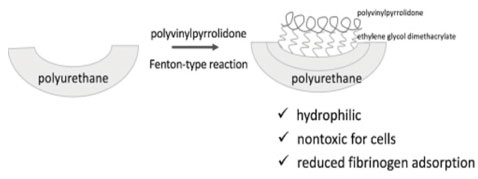

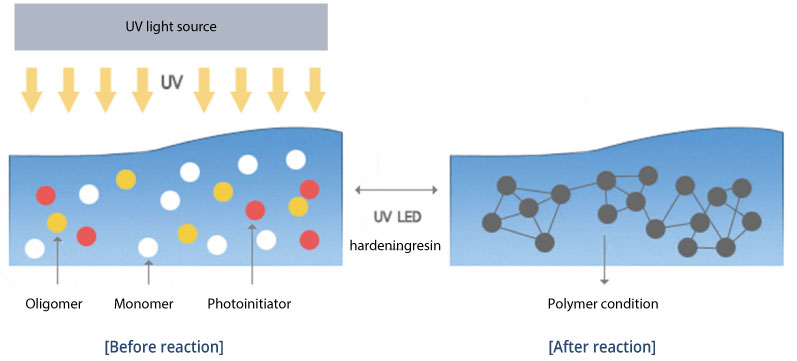

UV curable coatings

- Introduction

- Single(or double) coating, UV curable

- Heat cure version available

- A primer can be combined

- Advantages

- Eco-friendly

- Longer shelf and pot life

- Flexible

- Short curing time

- Substrates to be coated

- TPU

- PEBAX

- Silicone

- PE

- PMMA

- PVC

- PEEK

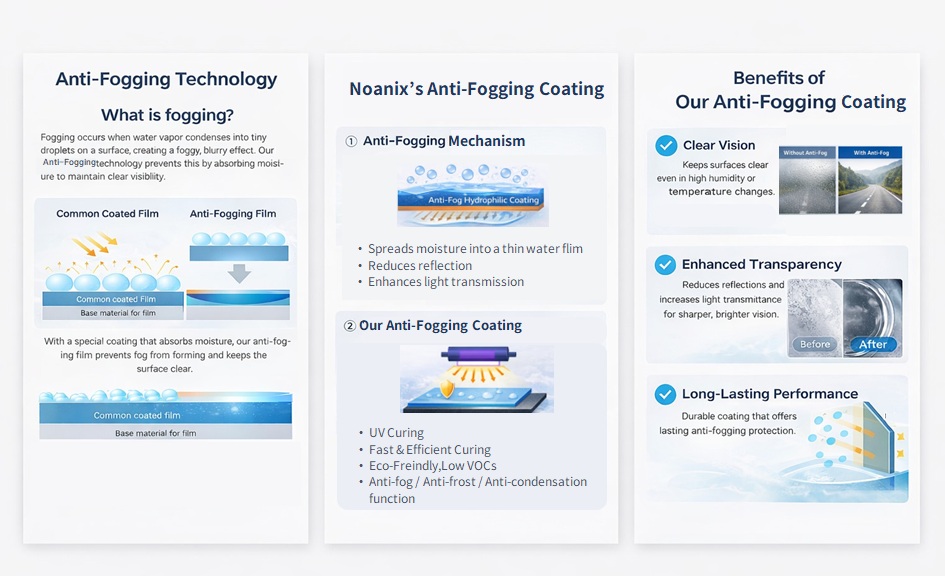

Anti-fog Coatings

Anti-Fog Coating

Prevents micro-condensation caused by temperature or humidity changes, keeping surfaces clear and maintaining high visibility.

Mechanism

* Moisture spreads into a thin water film, not droplets

* Reduced reflection, improved light transmission

* Clear and stable visibility

Key Features

* UV-curable & fast-processing

* Low VOC, eco-friendly

* Anti-fog / Anti-frost / Anti-condensation

Benefits

* Excellent anti-fog performance

* High transparency

* Stable under humidity & temperature changes

* Suitable for PET, PC, and various substrates