TECHNICAL OVERVIEW

기술자료

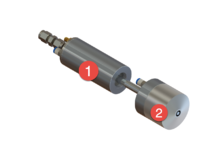

Ultrasonic Nozzle

Ultrasonic nozzles are a type of spray nozzle that uses high frequency sound waves produced by piezoelectrictransducers acting upon the nozzle tip that will create capillary waves in a liquid film. Once the amplitude of the capillary waves reach a critical height (due to the power level supplied by the generator), they become too tall to support themselves and tiny droplets fall off the tip of each wave resulting in atomization.

The primary factors influencing the initial droplet size produced are frequency of vibration, surface tension, and viscosity of the liquid. Frequencies are commonly in the range of 20-180 kHz, beyond the range of human hearing, where the highest frequencies produce the smallest drop size.

History

The phenomenon referred to as ultrasonic atomization has its roots in late 19th century acoustical physics, specifically in the works of John William Strutt, 3rd Baron Rayleigh, author of the definitive work The Theory of Sound. In 1962 Dr. Robert Lang followed up on this work, essentially proving a correlation between his atomized droplet size relative to Rayleigh’s liquid wavelength. Ultrasonic nozzles were first brought to market commercially by Dr. Harvey L. Berger. US A 3861852, “Fuel burner with improved ultrasonic atomizer”, published Jan 21, 1975, assigned to Berger Harvey . The first application of Dr. Berger’s work was in home heating oil burners, in an attempt to create a more efficient burner and conserve fuel during the 1970s energy crisis in the United States.

Subsequent uses of the technology include coating blood collection tubes, spraying flux onto printed circuit boards, coating implantable drug eluting stents and balloon/catheters, Float glass manufacturing coatings, anti-microbial coatings onto food, precision semiconductor coatings and alternative energy coatings for solar cell and fuel cell manufacturing, among others.

Ultrasonic nozzle applications

Printed Circuit Boards

The non-clogging nature of ultrasonic nozzles, the small and uniform droplet size created by them and the fact that the spray plume can be shaped by tightly controlled air shaping devices make the application quite successful in wave soldering processes. The viscosity of nearly all fluxes on the market fit well within the capabilities of the market. In soldering, “no-clean” flux is highly preferred. But if excessive quantities are applied the process will result in corrosive residues on the bottom of the circuit assembly.

Solar Cells

Photovoltaic and dye-sensitized solar technology both need the application of liquids and coatings during the manufacturing process. With most of these substances being very expensive, any losses due to over-spray or quality control are minimized with the use of ultrasonic nozzles. In efforts to reduce the manufacturing costs of Solar cell, traditionally done using the batch-based Phosphoryl chloride or POCl3 method, it has been shown that using ultrasonic nozzles to lay a thin aqueous-based film onto silicon wafers can effectively be used as a diffusion process to create N-type layers with uniform surface resistance.

Ultrasonic Spray Pyrolysis

Ultrasonic Spray pyrolysis is a Chemical vapor deposition (CVD) method utilized in the formation of a variety of materials in thin film or nanoparticle form. Precursor materials are often fabricated through sol-gel methods and examples include the formation of aqueous silver nitrate, synthesis of zirconia particles, and fabrication of solid oxide fuel cell SOFC cathodes.